Call us! (877) 219-3936

Call us! (877) 219-3936

Whether you are just beginning to weld or are a welding professional, chances are there are some techniques you’ve had up your sleeve since you’ve started. Like any profession, welding requires a basic understanding of standard techniques and methods in order to get the job done the right way.

If you are a beginner, you may find yourself wondering what these techniques are, whether you already know them, or how to utilize them. Don’t worry! We will go over all of the welding techniques that even the pros still rely on, and how to apply them to your welding processes. Join us as we delve into the mechanics of welding, and how certain techniques are as unforgettable, and important, as using the pedals on a bike.

A stringer bead is most often the first welding technique that a beginner learns. In order to make a stringer bead, you drag your electrode straight across the seam. There is no motion aside from dragging or pulling.

Intermittent welding is also known as staggered welding. An intermittent weld is defined as making a weld for two, three, or four inches, then skipping that same distance and welding again. After beginning an intermittent weld, one welds at the other end of the joint, and then goes back to the other side and fills in the space between welds. More often than not, the first weld beginners learn is a string bead: a continuous straight line.

Weave bead welding involves making a weaving pattern in order to cover a larger surface area. This motion allows you to make cover welds over stringer beads, otherwise known as multipass welding. This technique is used when you are layering welds among one another (making multiple welds on the same seam).

Below are some of the most common weave bead welding techniques used by professionals. Becoming familiar with them could prove to enhance your welding abilities. Here are some of the most common techniques:

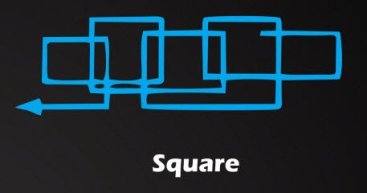

This technique is applicable whether you are welding in the flat position or the vertical welding position.

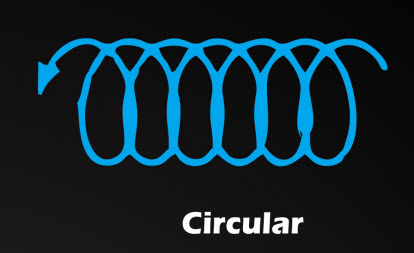

A circular motion is a good skill to possess when welding in the flat position. This technique is also great for surface welds

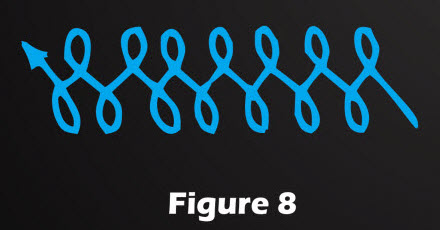

The figure eight and zigzag weaving technique is a good procedure for making a cover pass when you are either in the vertical welding position or the flat welding position.

The J welding technique is most suitable for lap joints and butt welds.

This technique is best used when you find yourself in the overhead welding position or the vertical welding position.

This technique is usually used for multipass welding and/or string beads. This technique is applicable for all welding positions.

When welding a thick plate one will require more than just one stringer bead weld to fill the gap and make the weld strong. This requires a multipass welding. A multipass is best defined as laying several beads on the joint. Multipass requires the use of a weaving technique after laying a stringer bead. Making a short pause when you weave will help you avoid any undercutting and achieve perfect fusion of your material.

A tack weld is often used to maintain stability of the metal as you weld. Tack welding is also a great process for avoiding any unwanted distortion. For instance, one should tack weld each corner when welding square tube. However, you should first put the metal in a vice and clamp it, then tack weld each opposite corner to keep the gaps uniform around the tube.

These have been a few common techniques that are used by welders of all skill sets. If you require a more visual representation of these methods, check out Two Guys Garage as they demonstrate some of these basic techniques in this video:

Leave a comment